The idea

|

Because we live in Constanta, the largest port on the Black Sea, we noticed the unpleasantness of algae: growing on ships’ hulls (reducing the speed and increasing the fuel consumption), sitting on shoresides (making it harder to reach the water and producing obnoxious smells). However, we also noticed its potential being able to make our ecosystem better. We want to produce biodiesel from algae in order to solve two problems: reduce the burning of fossil fuel which causes chemical pollution of the atmosphere and get rid of the unwanted algae which bothers locals and tourists. |

|

|

Our plan is to create a website, “The Algae Club”, to sell the biodiesel, while the corporate offices and production facilities are spread out across the globe. It could ultimately contribute to increasing the share of sustainable energy, preserving non renewable reserves, reducing the volume of fossil fuel imports, toxic waste and protecting the environment. |

What is it?

Biodiesel is an environmentally friendly fuel that successfullyreplaces diesel. Diesel is produced from petroleum, and this is a non renewable resource. The specialists predict that the current petroleum resources will last only for a few more decades. The burning of fossil fuel also causes chemical pollution of the atmosphere.

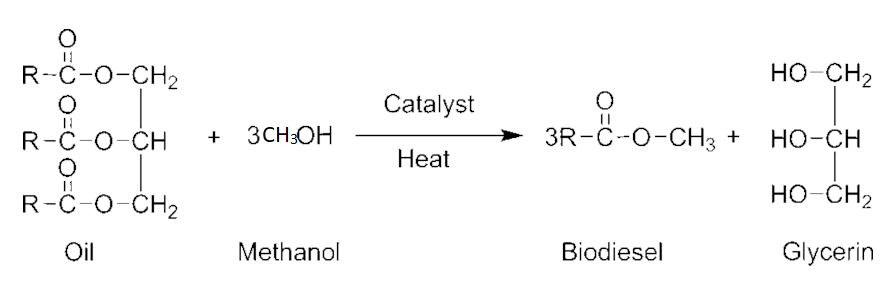

A few years ago, in Hong Kong, biodiesel was produced for the first time, from vegetable oils, adding ethanol or methanol and

caustic soda (NaOH) or potassium hydroxide (KOH), through a simple production method.

Biodiesel can be used for any vehicle without modifying the engine. This biofuel reduces CO2 emissions from the atmosphere by 80% and SO2 emissions by 100% compared to diesel. Compared to traditional diesel, the price is reduced and the toxic emissions produced are much less, it does not contain sulfur, allowing the use of catalysts and does not affect fuel consumption or engine speed.

It is less inflammable, which is an advantage for storage and transport, the ignition point of biodiesel is 150 degrees compared to 70 degrees for diesel fuel. Biodiesel production has several technological advantages, the most important is high energy efficiency.

Furthermore, algae are one of the most efficient producers of plant oils. Microalgae are a much more efficient option of converting solar energy into chemical energy for fuel, due to their simple cell structure and high photosynthetic efficiency compared to other plants. They grow submerged in water, providing the necessary amount of hydrogen.

How does it work?

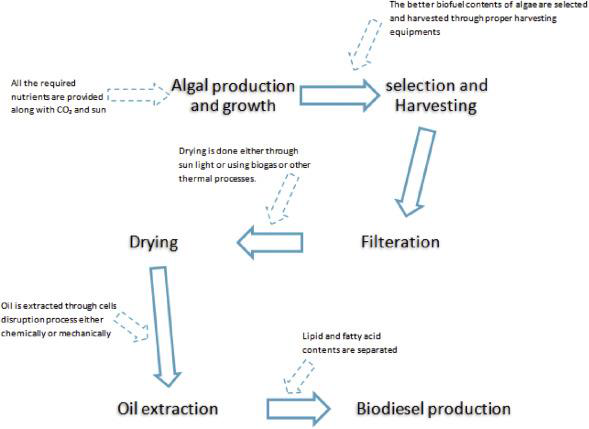

|

Step 1: Some species of algae were identified to have good fatty acid values. In the same way, some algae have more components of fatty acids by their dry masses. The simple method of fatty acids extraction and separation of biodiesel is the blending method on small or experimental scale Step 2: The drying technique mostly used is spray drying, drum drying was also suggested. |

|

|

|

|

Step 3: Oil extraction: One of the ways for extracting oil from algae works very much like the technique used in an oil press. Another common method is the hexane solvent method. When combined with the oil press method, this step can yield up to 95% of available oil from algae. It utilizes a two step process. The first is to utilize the oil press method. Then, instead of stopping there, the leftover algae is mixed with hexane, filtered and cleaned to remove all traces of the chemical in the oil. |

|

|

Step 4: Biodiesel production: Once the oil has been extracted it must be refined to become a diesel fuel. Transesterification is the most common method. In the process of transesterification, methanol and a basic solution are mixed and reacted with the oil. This produces biodiesel and glycerin byproducts. The biodiesel is then washed and filtered before it is ready for public use. |

|

|

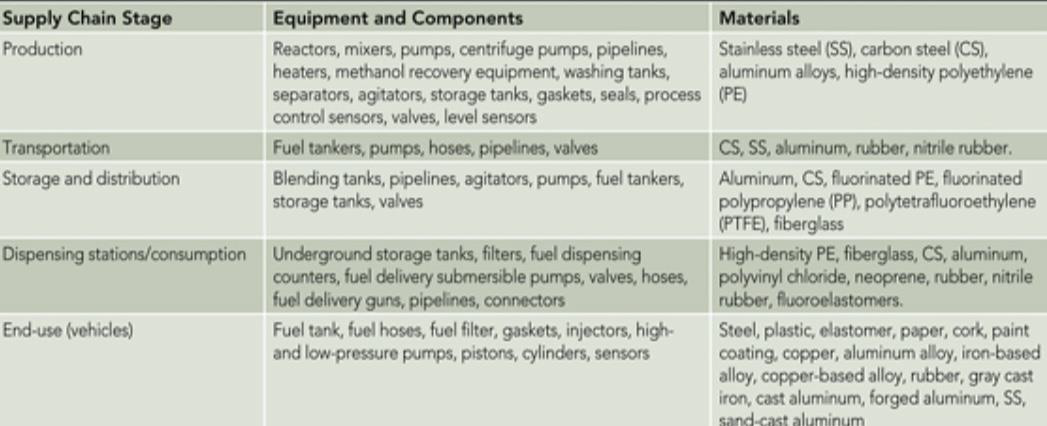

The necessary resources:

|

|

|

The experiment: We tried to do an experiment to produce biodiesel. We used the following equipments and substances:

|

|

After collecting the macrophyte algae from the Cholophyceae group, we washed them in two water baths to remove impurities, and then we extracted the chlorophyll in ethyl alcohol. We added n hexane over the discolored algae and extracted the oil using the reflux installation.

The glass flask is placed in a water bath, the substance in the flask boils, evaporates through the refrigerant where it condenses, and the drops return to the flask, avoiding thus the evaporation of the substance.

The extraction lasts around 9 hours. The obtained mixture (n-hexane + oil from algae) is distilled to separate the two substances.

The recovered n-hexane can be reused and we apply the same procedure to the chlorophyll extract, so the ethanol is recovered and can be reused.

Starting with 15 g of algae , we obtained approximately 15 ml of oil . Now that we have the oil, we apply the quantities that we mentioned and obtain algae biodiesel.

Bibliography

- https://www.sciencedirect.com/science/article/pii/S1978301917300190

- https://www.treehugger.com/making biodiesel from algae 85138

- https://energyeducation.ca/encyclopedia/Processing_algae

- https://wikicro.icu/wiki/Algae_fuel#Use_of_byproducts

- https://www.researchgate.net/figure/Transesterification reaction of oil with methanol in the presence of sodium hydroxide as_fig1_271433213

Proiect realizat de:

Ardeleanu Arina Maria

Mirela Mate

Profesor îndrumător:

Prof. Bucovală Carmen